Precision Screw Machining

High Quality & High Volume

Made in the USA for Over 60 Years

Since 1959, JCGibbons has provided custom screw machining services to customers from all over the U.S and Canada. Operating multiple shifts to handle your high volume needs. All parts are made in the U.S.A. from our large 22,000 square screw machining shop based out of Livonia, Michigan.

ISO certified, our screw machining capabilities allow us to manufacture high quality, high volume precision machined components for any industry. From 20,000 piece minimums to millions, we consistently deliver on-time for industries such as automotive, defense, plumbing, aerospace, HVAC, oil and gas, electrical, alternative energy, and more. If you’re looking for a screw machine shop near by, look no further!

Get a Fast Quote Today

Need a quote in 24 hours from a qualified supplier? Whether your line is down or you’re looking for a new screw machine vendor, we’re known for our fast response!

Screw Machining Services

We Invest in Efficiency

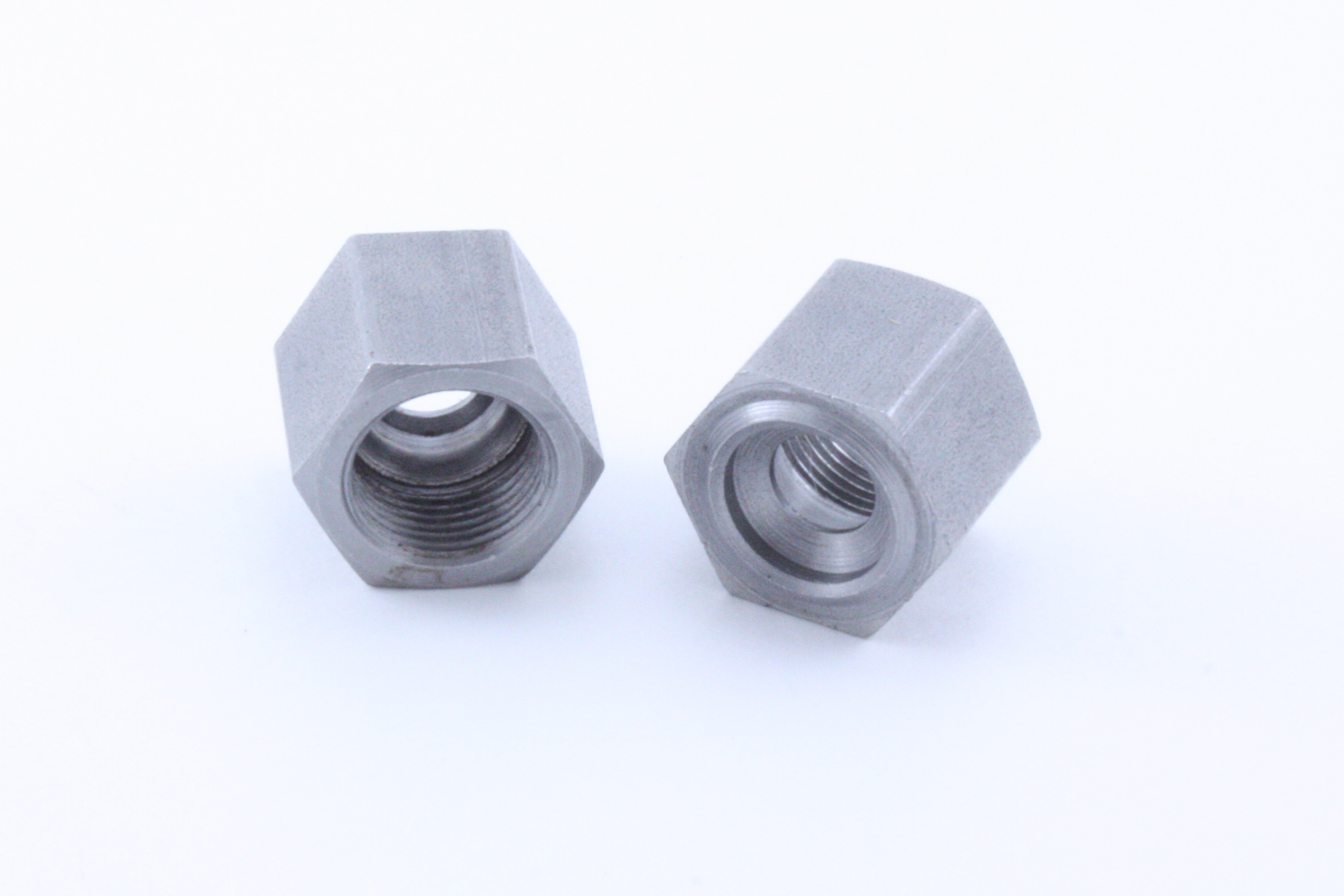

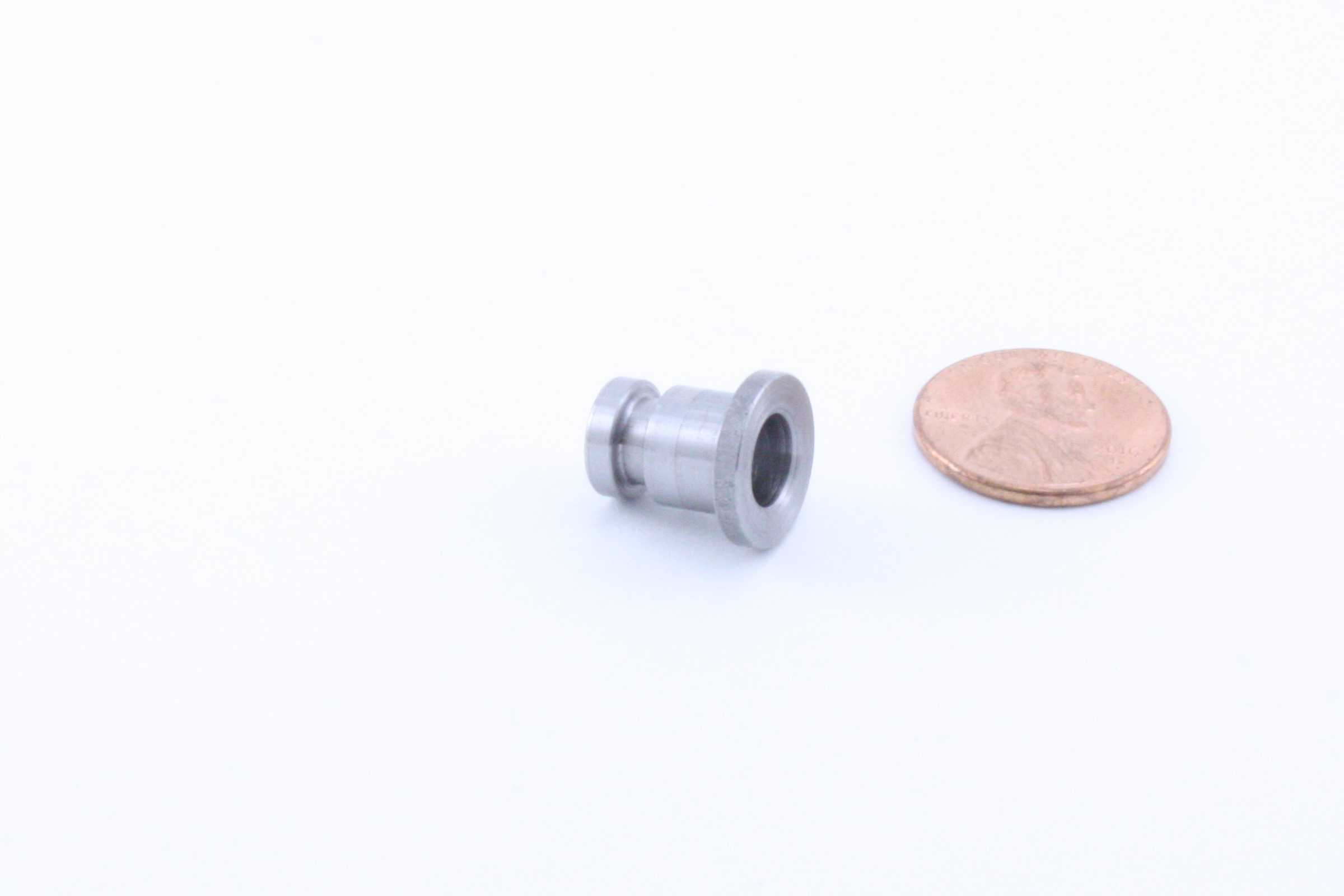

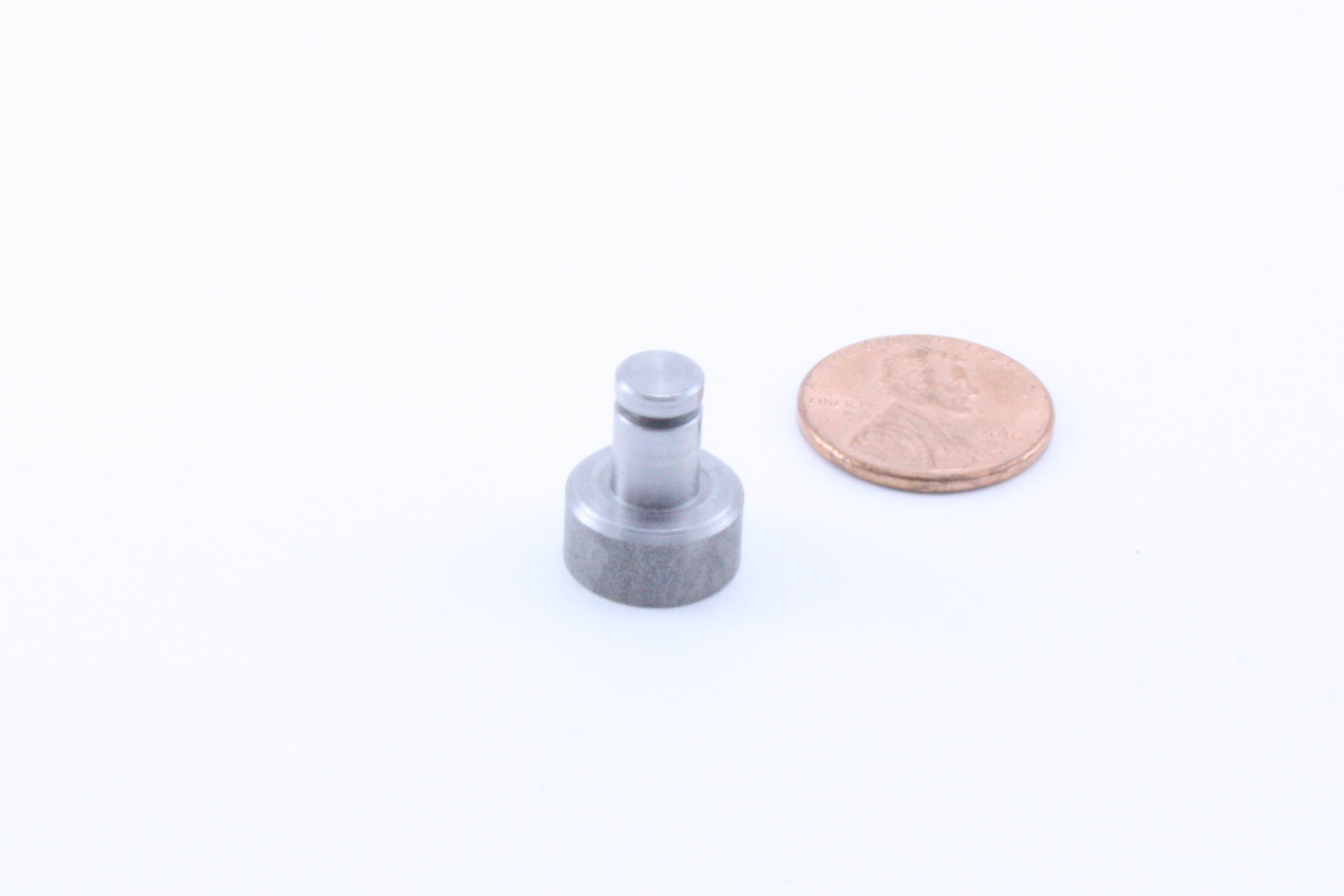

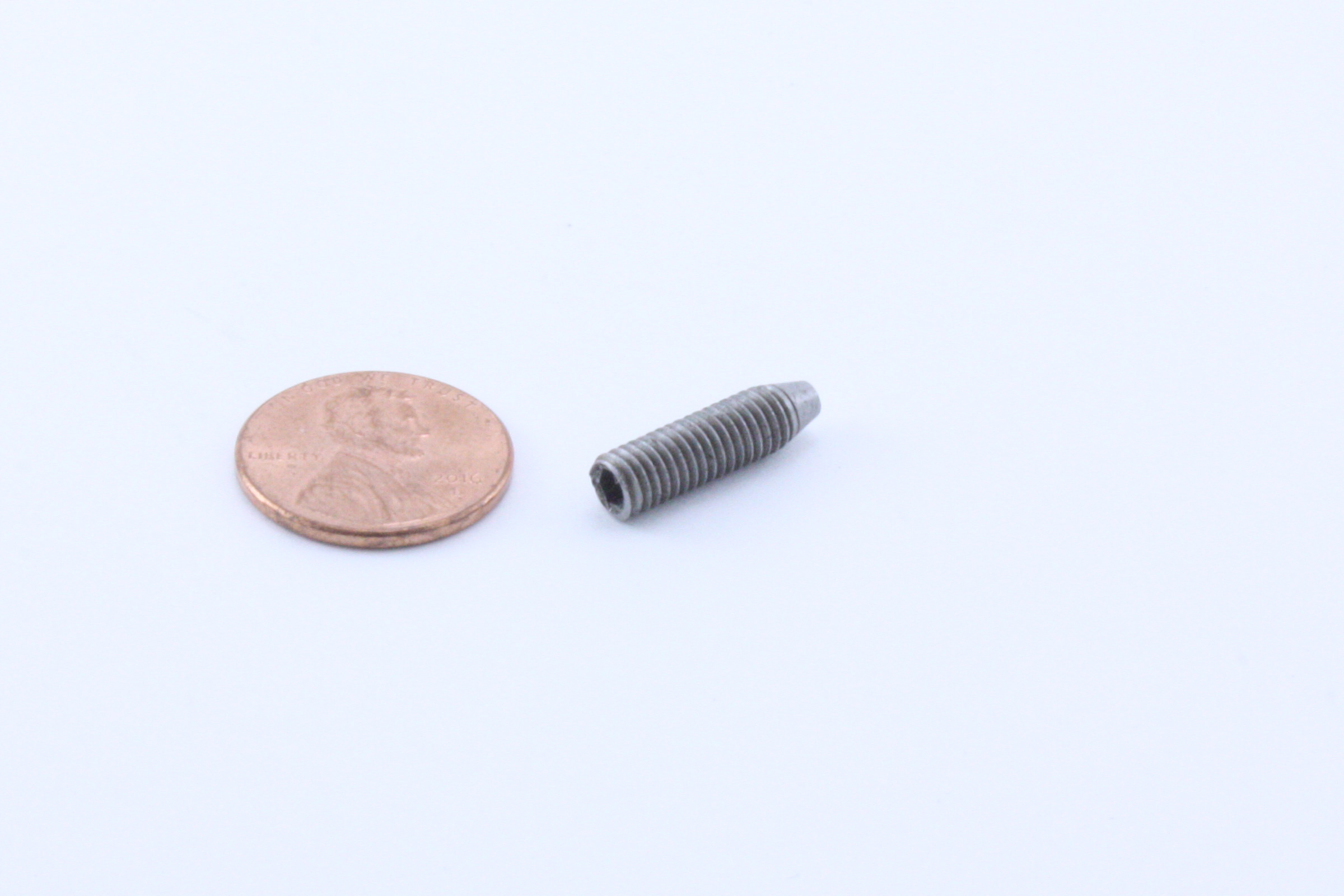

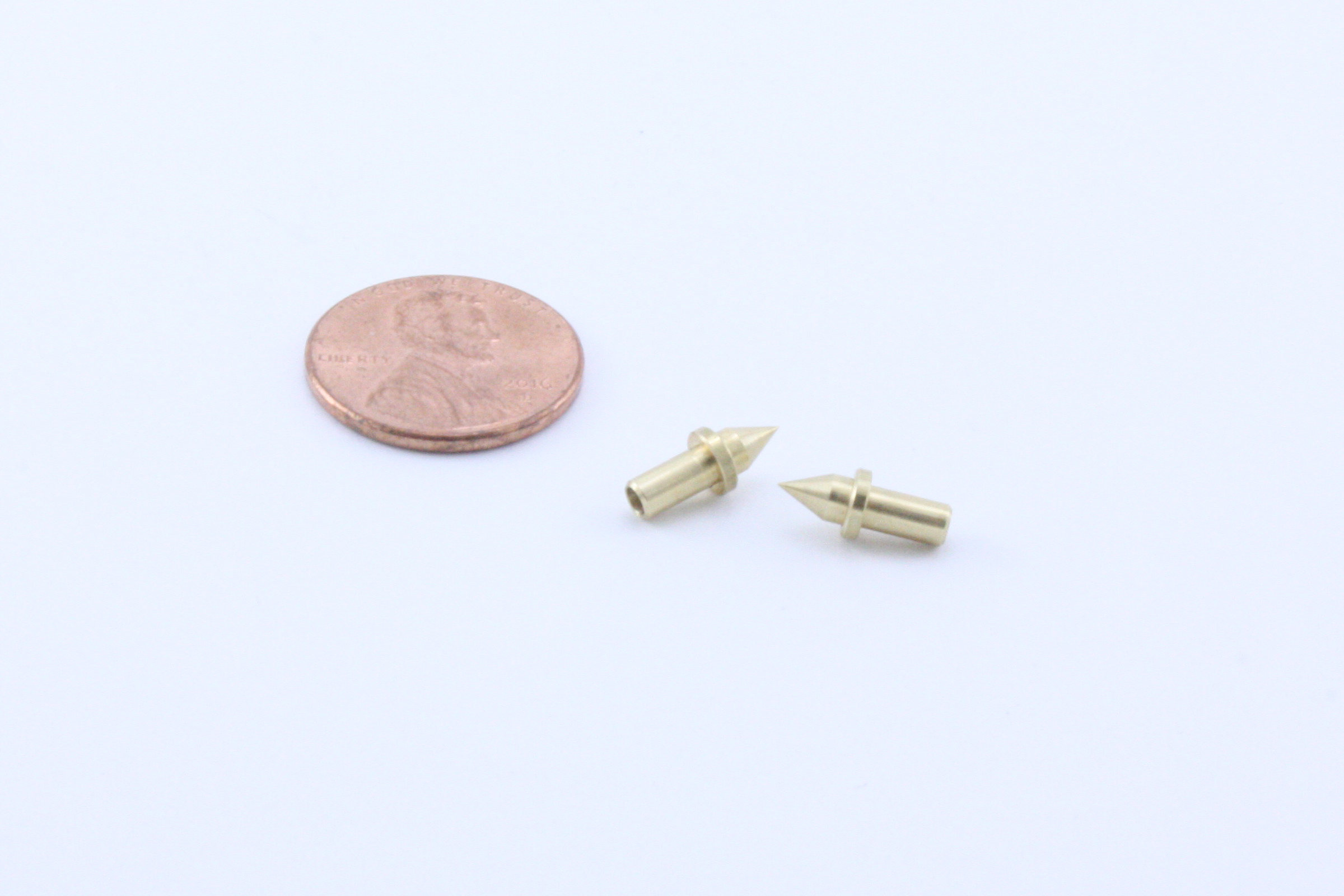

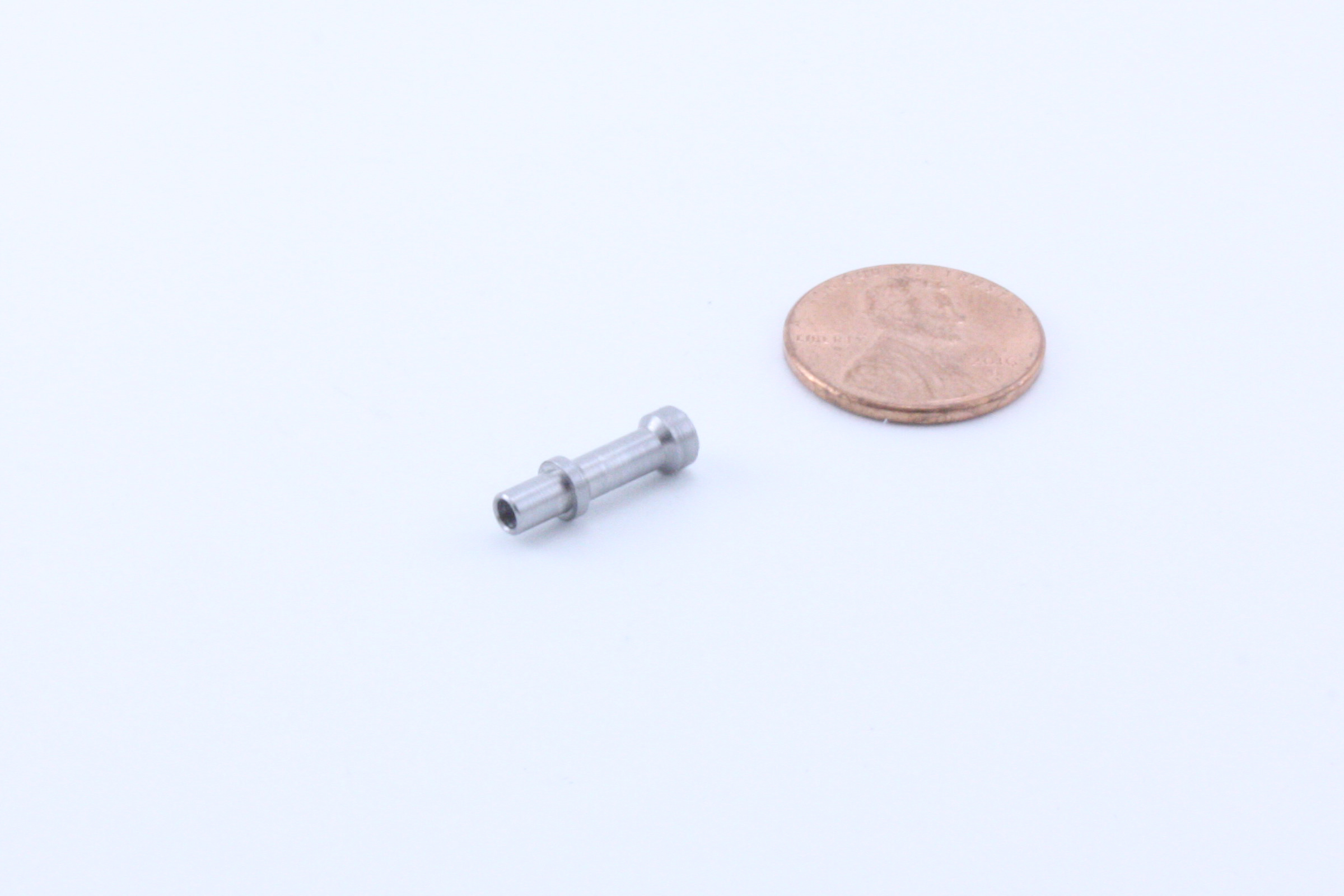

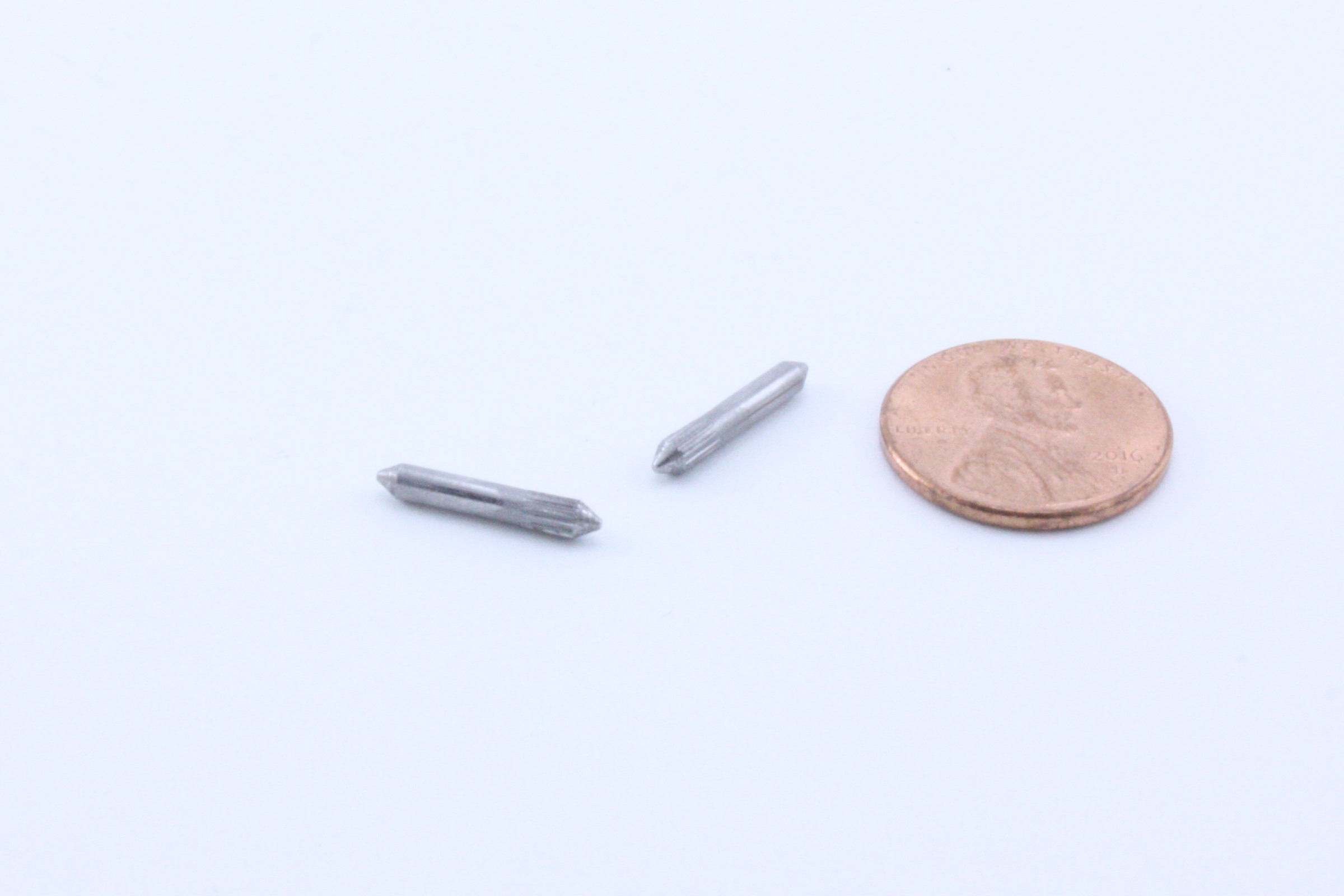

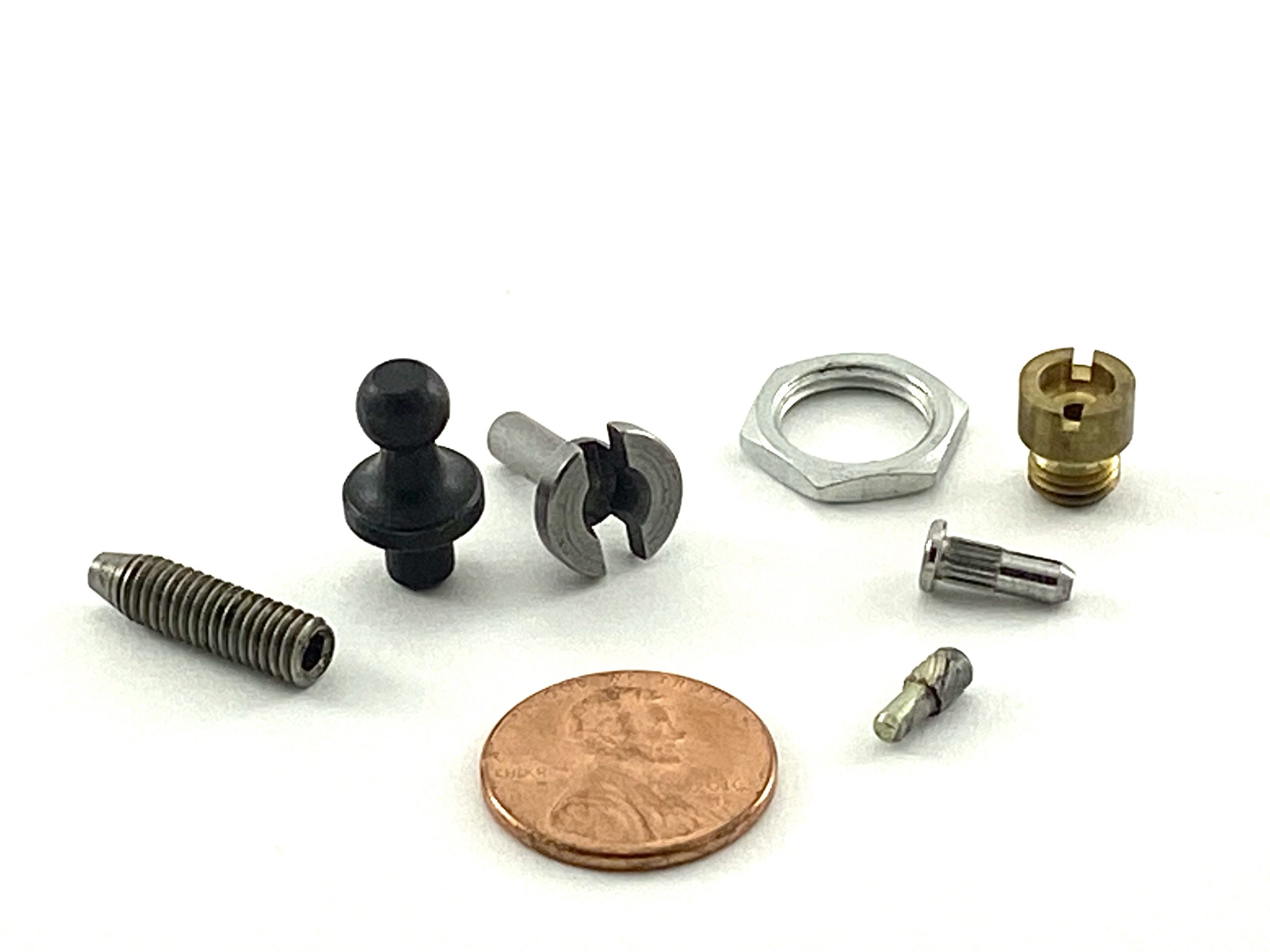

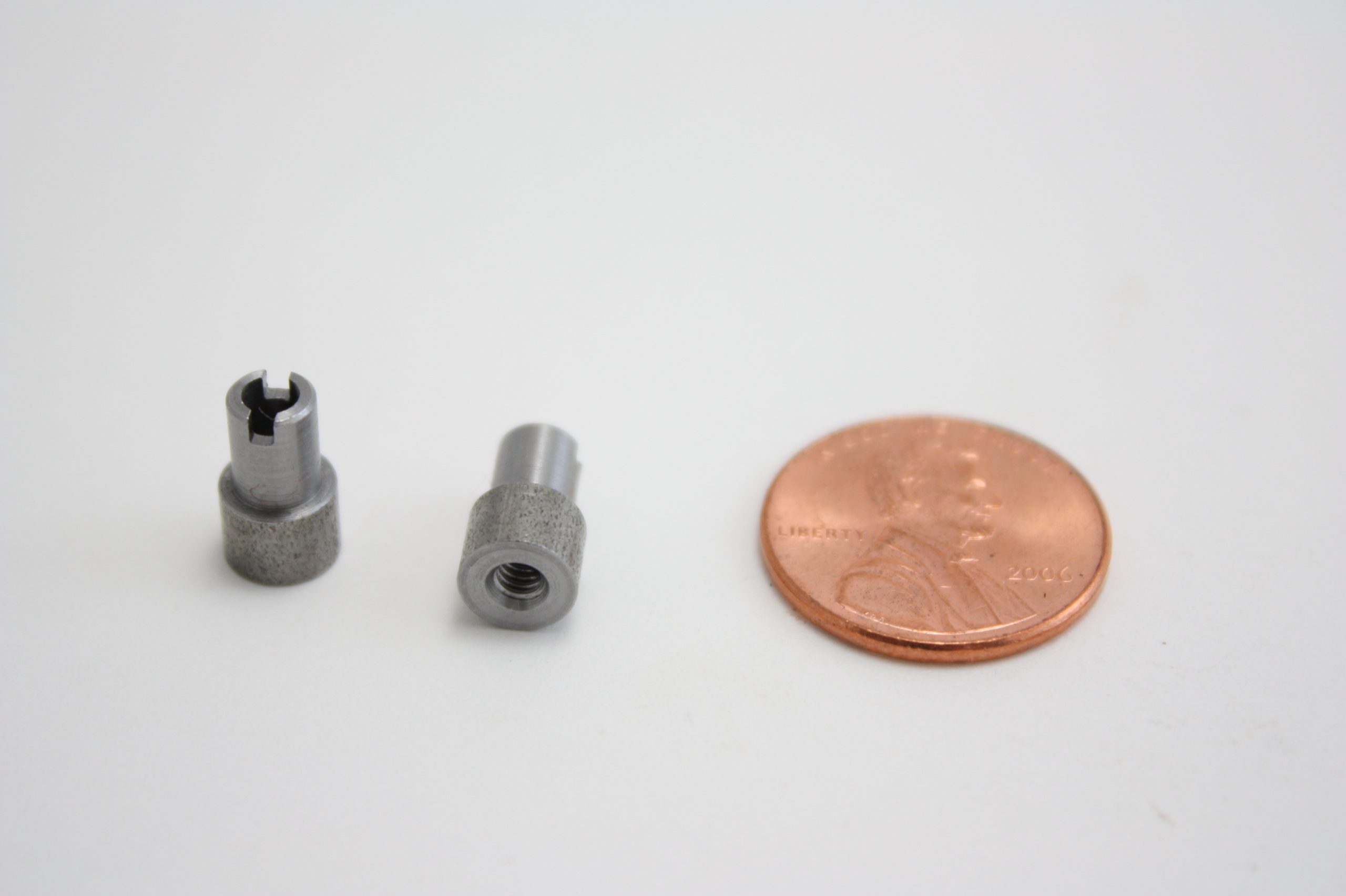

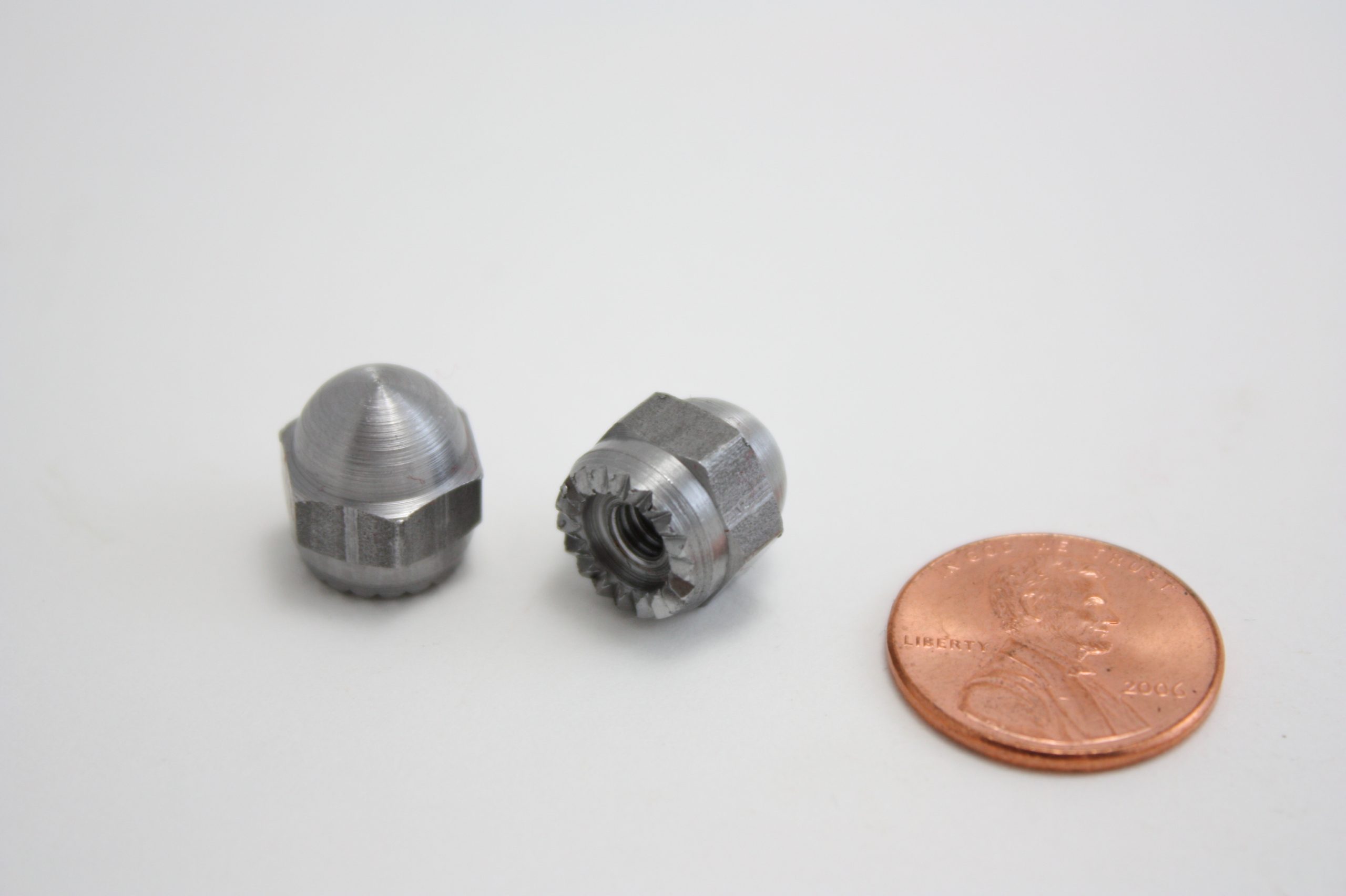

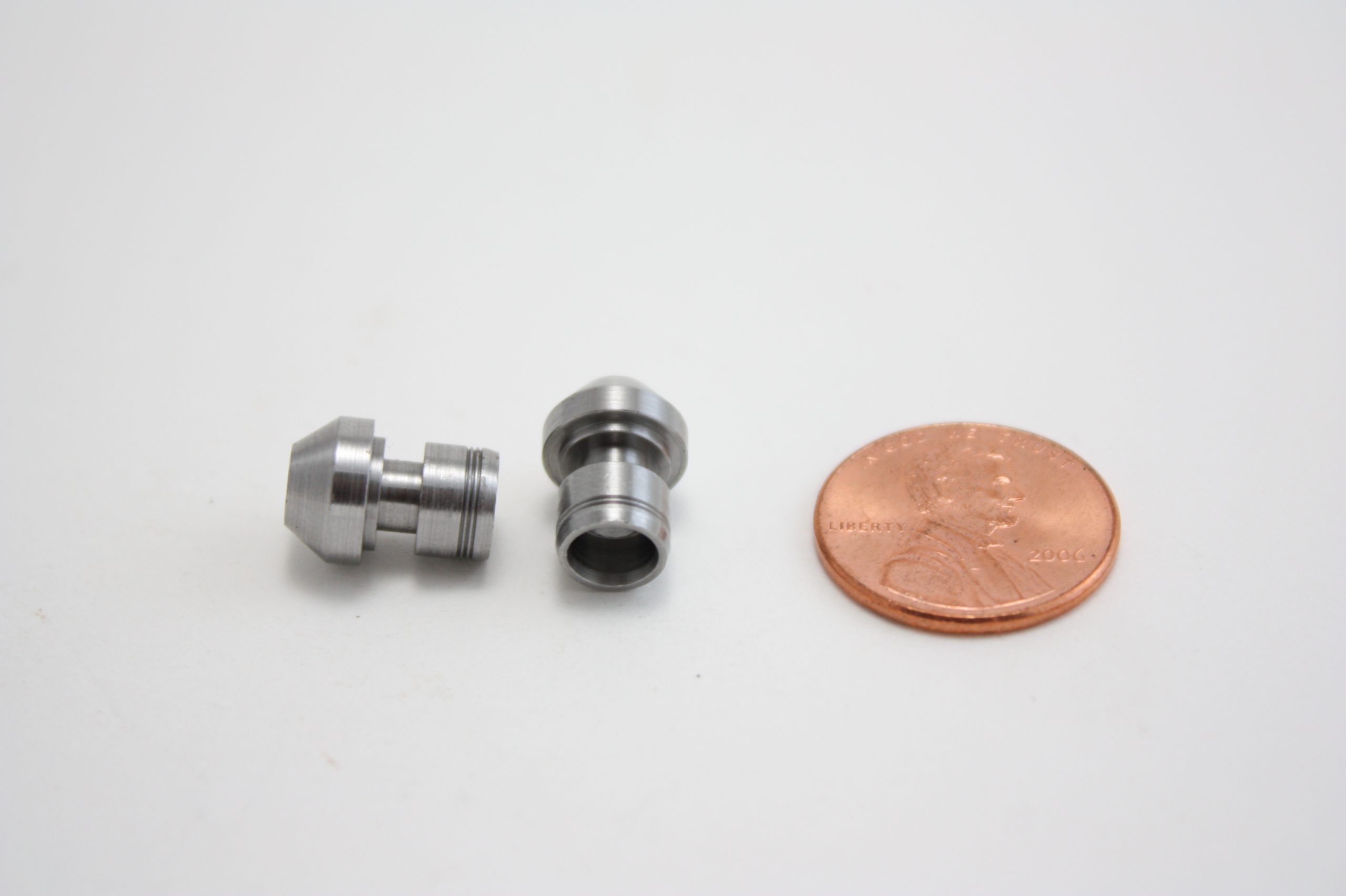

Davenport screw machines manage stock size from 3/32 round to 7/8 round. Davenports can also turn hex stock and square stock to almost any geometry. Typical products turned off a Davenport are fittings, compression limiters, pins, spacers, ball studs, nuts, sleeves, bushings, retainers, dowels, rivets, tube nuts, inserts, compression fittings, sleeves, plugs, screws, knurled pins and lock screws to name just a few. Cycle times vary but can be as fast a 1.5 seconds and up saving you money. The faster that part can be machined the more money that we can save you.

Manufacturing small parts is what our screw machines do best! Through our machine upgrade and rebuild program JCGibbons can continue to manage a tolerance of +/- .0008″ on diameters. This preventative maintenance program is one key component as to why JCGibbons is superior to other screw machine companies. Currently we are operating 28 Davenports with real estate to add additional capacity.

Small and Large Part Manufacturing Experts

Attachments are what give our screw machines an advantage. The use of attachments for procedures such as cross drilling, slotting, thread rolling, and flat generation, allow screw machines to perform a wide variety of machine operations while maintaining the fastest cycle times in the industry. The more tooling in the cut at once saves time and money and screw machines have this figured out. See a list below of the common attachments that help deliver parts complete in one operation without costly second operations.

Extra Processing and Treatment? No Problem!

With over 60 years in business JCGibbons has developed an outstanding vendor list that allows us to processes those parts that require heat treat, plating, thread rolling, deburring, cleaning and mag inspection to name few. We will manufacture your part complete.

Our Specialties

Screw Machining

Davenport Screw Machine

Attachments

Screw Machining Materials: Aluminum, Steel, Brass, Stainless & More

Small run or high volume, our CNC department has access to both the mills and warehouses and can secure and manage almost any grade of material. From cold finished carbon steel, to non non-ferrous metals and plastics, our customers also can supply us with cold and hot forgings or we can supply and stock needed materials.

Cold Finished Carbon Steels

Alloy Steels

Stainless Steel

Aluminum

Red Metals & Plastic

Our Customers

An ISO certified company since 1998, JCGibbons is considered a preferred supplier to well over 100 customers due to our Low PPM’s, outstanding customer service and fast, on-time product delivery. Our customers appreciate our communication and ability to save the day on difficult jobs, line down situations or just your routine orders.