Machine Shop Adds a Robot — And Staff

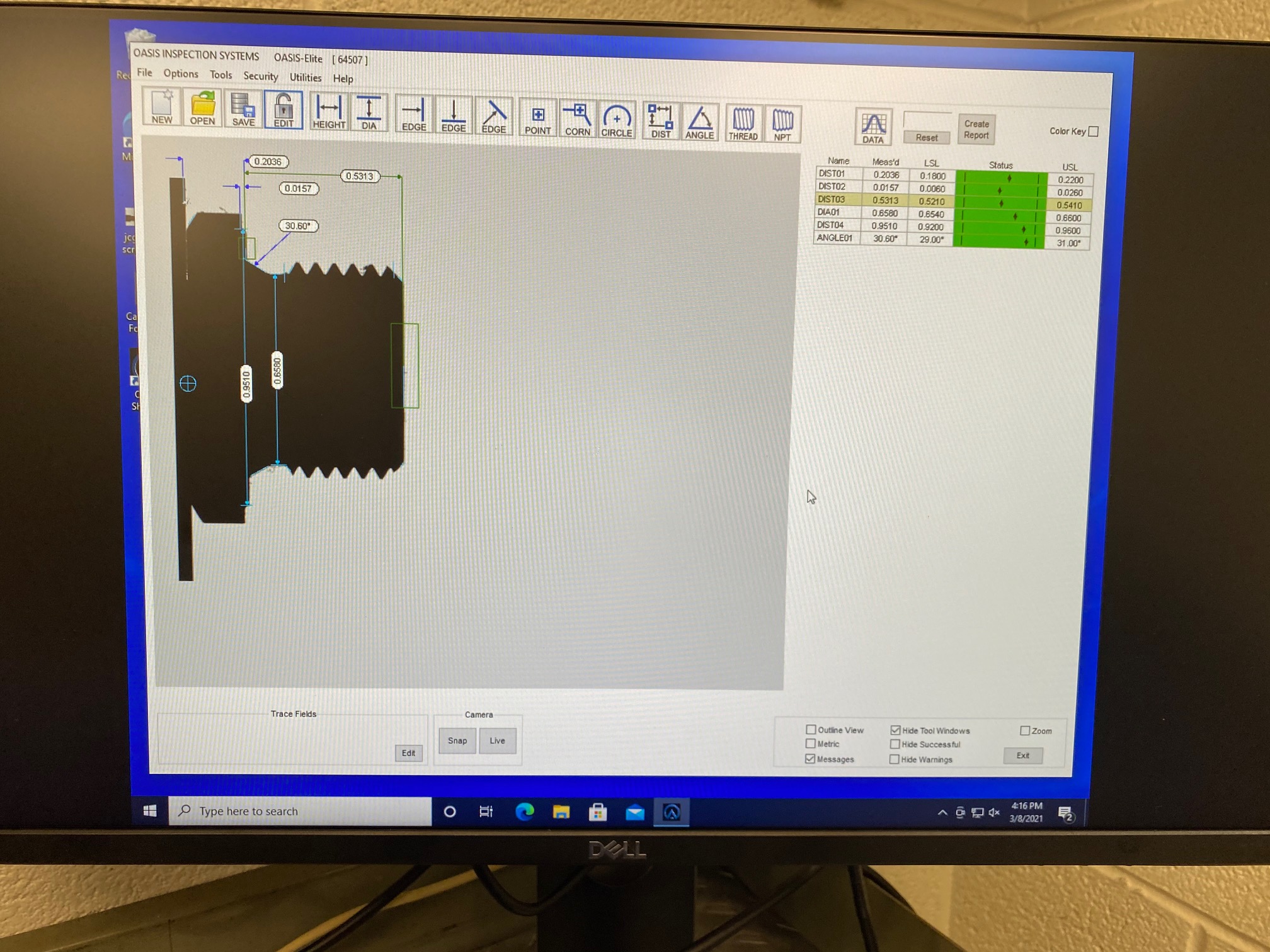

Livonia, Michigan based specialty CNC machining and screw machining shop JC Gibbons recently partnered with the Michigan Manufacturing Technology Center to perform a technology assessment. The goal of the assessment was to identify areas of technology deficiencies. This led to the purchase of a UR5e Universal Cobot and netted a foothold in Industry 4.0.

The Cobot UR5e is a robot intended for direct human robot interaction within a shared space, or where humans and robots are in close proximity. Cobot applications contrast with traditional industrial robot applications in which robots are isolated from human contact.

Huge Productivity Gains Lower On-Shore Parts Costs

JC Gibbons Vice President Dan Gibbons knows what his customers want, commenting “We know everyone wants high quality with near zero defects, and we’ve been delivering on that promise for some time. However, cost is always a concern. This machine has helped us deliver jobs with more competitive pricing”.

These results have been measurable. With the addition of the Cobot, JC Gibbons has now seen a 40% increase in throughput. More recently, JC Gibbons has been on a growth streak and hiring new employees in a very competitive market. The addition of the new machine has resulted in an increase in team moral and helping this growing company retain employees.

Technology Helping Ensure On-Time Delivery

While already having a long history of on-time delivery of both small and large part runs, the Universal UR5e Cobot will assist in improving on time delivery by increasing efficiencies and throughput, reducing repetitive motions by humans resulting in less time off and burn out and continuing to meet the expectations of our customer base.

JC Gibbons has satisfied dozens of customers by utilizing the UR5e Cobot. Ford, GM, Stellantis, Caterpiller, John Deere, Meritor, Bendix, Otis, Roush to name just a few of the companies that have benefited from the use of our Cobot’s.

See a highlights video below for more on this story.